GOOD NEWS : We have developed a new kind of autonomous power supply for our OH Gas Generators - a Magnetic Power Generator. We have a small 4W prototype sized 250*200*50mm working already for the last 4 months, non-stop, with no external energy or fuel supply at all. This simple and motionless generator could replace the heavy turbine-generator and engine-generator equipment in our OH Power plants and MOH Gas Fuel Refineries. We are also working on developing a scaled-up compact powertrain for all kind of vehicles, based on this invention.

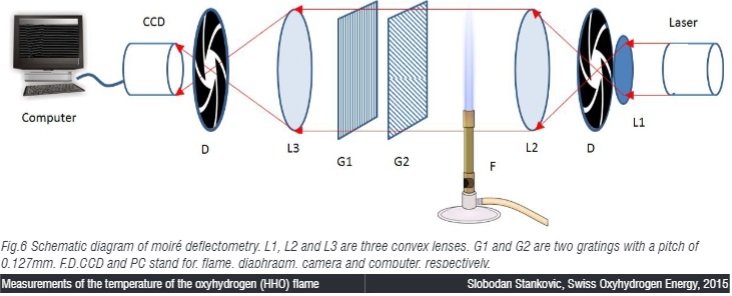

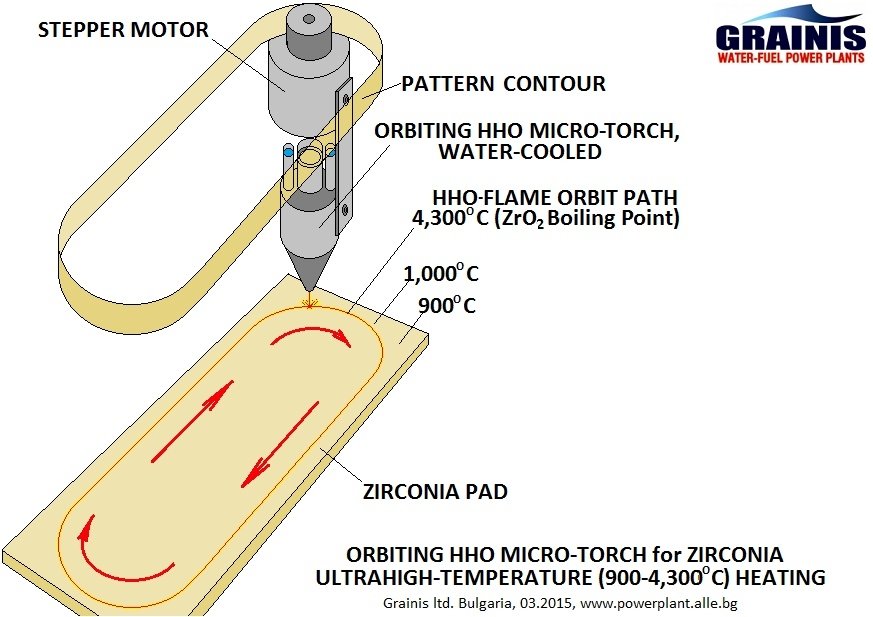

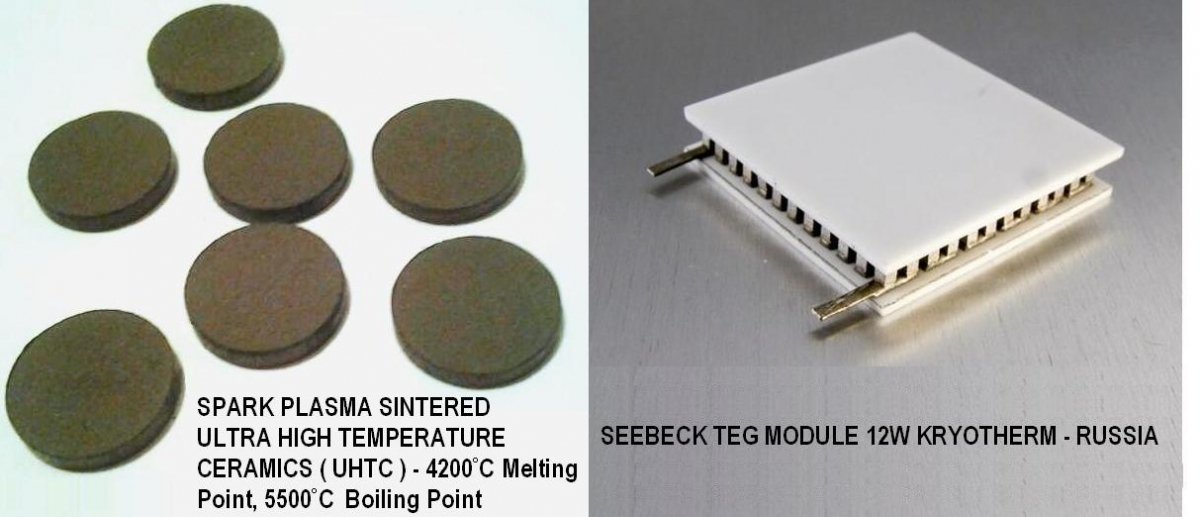

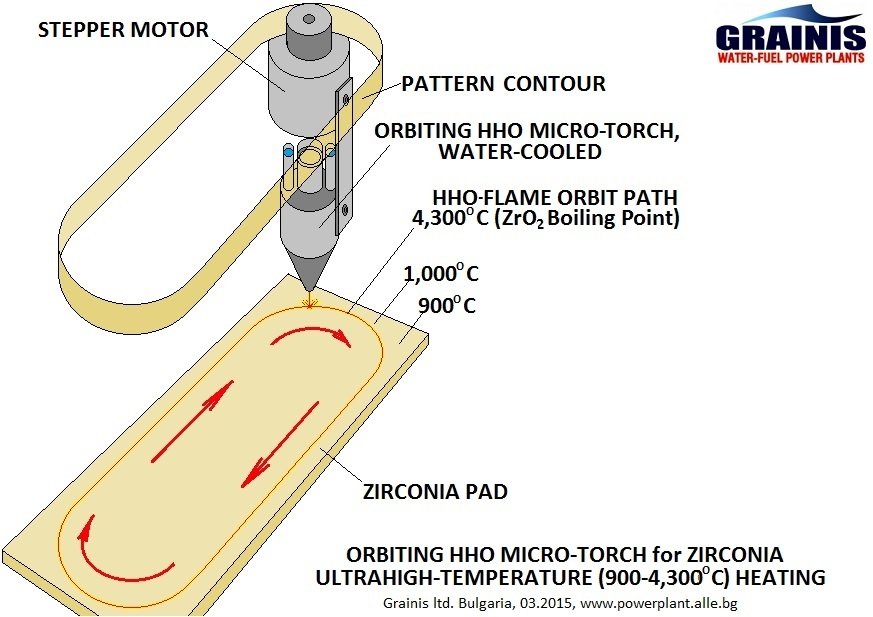

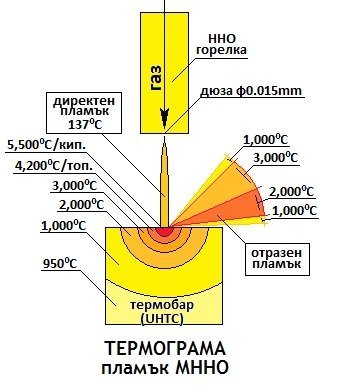

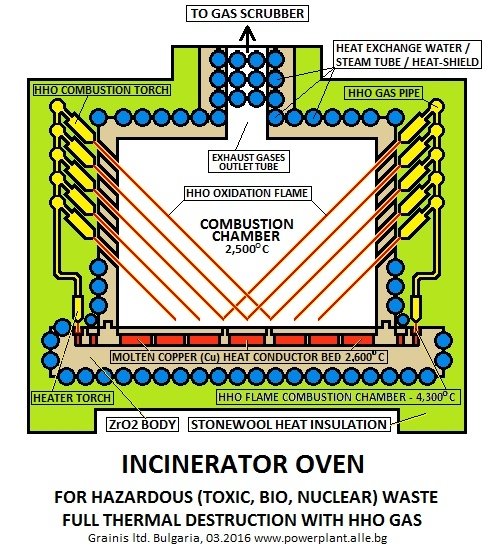

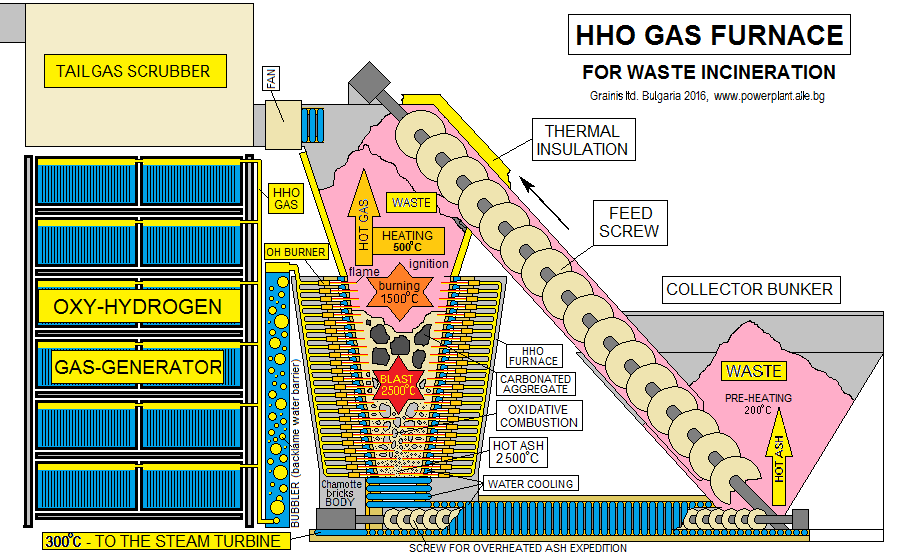

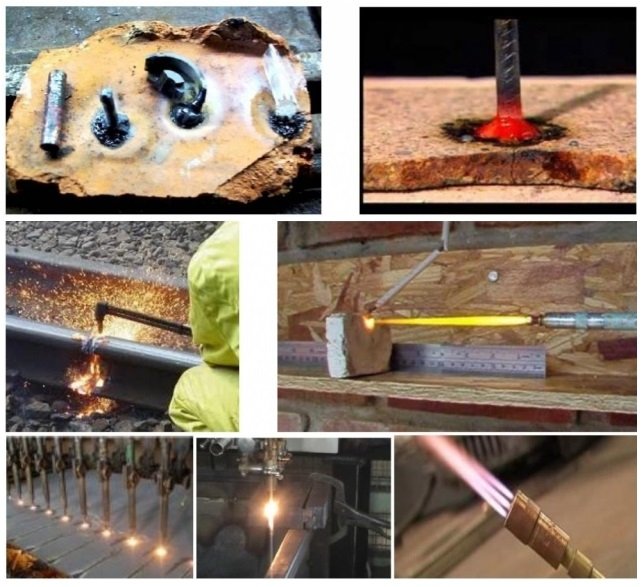

We are GRAINIS LTD - a Bulgarian R&D company, working since 2005 on a technology for producing low-cost Oxygen-Hydrogen (OH, Browngas, HHO) Stoichiometric Gas Mixture, by our high-effective (0.4Wh/l), Modified Water Electrolysis. OH's gas flame is a kind of Cold Plasma : http://www.researchgate.net/publication/281971041 with unique properties - it's own temperature is only about 140 deg.C high, but it generates giant energies and ultra-high temperatures over 5,500 deg.C inside some UHTC ceramic materials it heats up. The reason for such incredible behavior is the flame's Plasma nature : ionized (electrically-conductive) gas flame.

When something burns with a flame, electrons are torn from their atoms as the atoms rearrange to form new molecules. Usually they get re-captured by the molecules, and this is one of the reasons why flames glow -- the electrons emit light as they lose energy spiraling in from their paths free through the air to being caught in orbits in the new molecules.

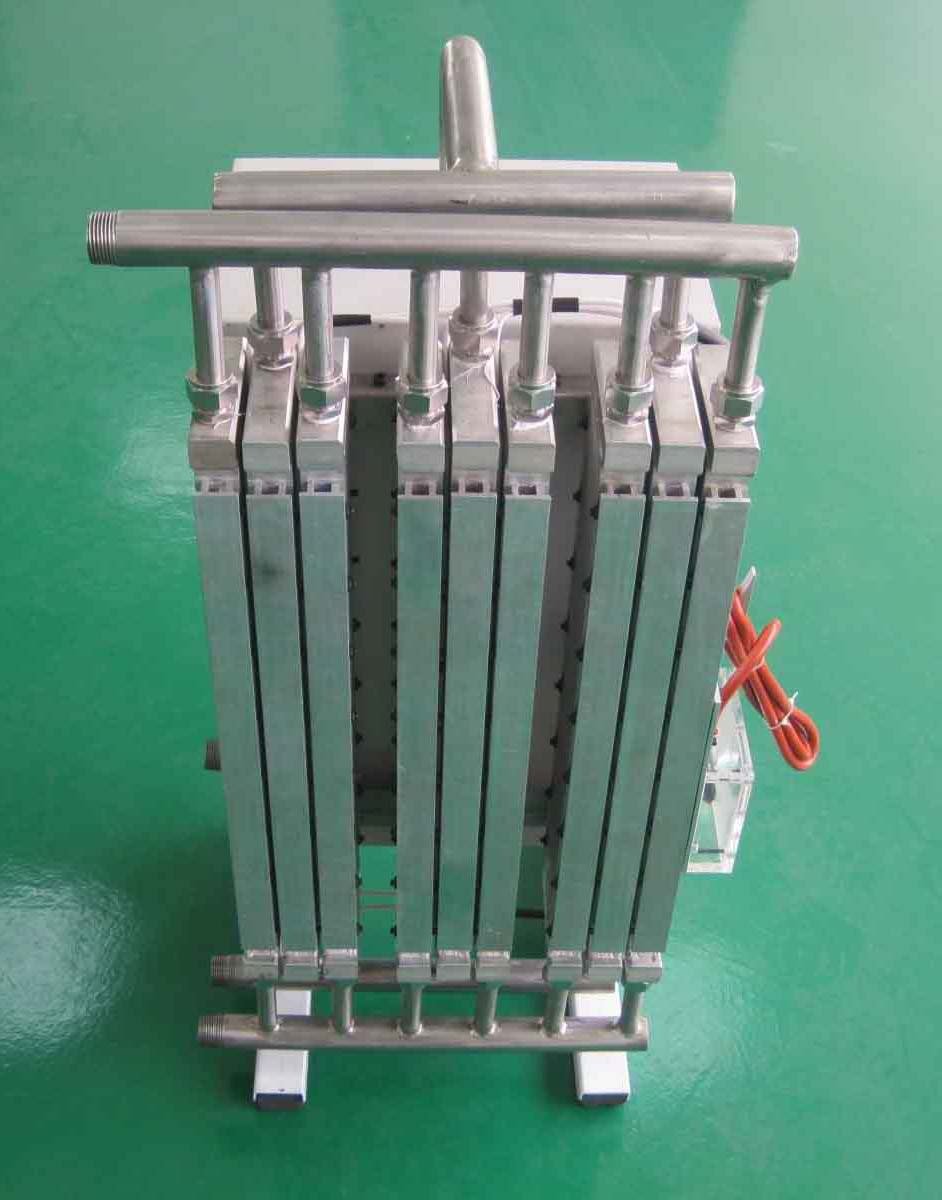

As a result of the 10-year researches of our team of scientists, we have discovered an ultra-high effective method for generating OH gas by a modified water electrolysis, with as low as 0.4Wh/L for OH and 1.1Wh/L for Pure Hydrogen power consumption only, or about 5 times less, compared with the regular 3.7-4.5Wh/L consumed by the modern OH Gas-Generators, offered today by many firms on the world's market.

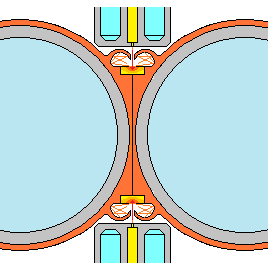

We use PWM, PSM and PPM electronic modulators for the supplied current's super-critical fragmenting, UV-LED photo activation, compulsive electrolyte re-circulating diffusion, special chemical catalysts and sealants. Our device uses the unique property of ionization the electrolyzer cell's electrode plates by a shock-current impulse lasting one millisecond, followed by 99 milliseconds of "silence" with NO current supply at all, but continuing OH gas production. These cycles are being repeated about 10 times in a second.

We use PWM, PSM and PPM electronic modulators for the supplied current's super-critical fragmenting, UV-LED photo activation, compulsive electrolyte re-circulating diffusion, special chemical catalysts and sealants. Our device uses the unique property of ionization the electrolyzer cell's electrode plates by a shock-current impulse lasting one millisecond, followed by 99 milliseconds of "silence" with NO current supply at all, but continuing OH gas production. These cycles are being repeated about 10 times in a second.

So we can say that we produce a lot of gas with almost zero energy, without violating any single law of physics.

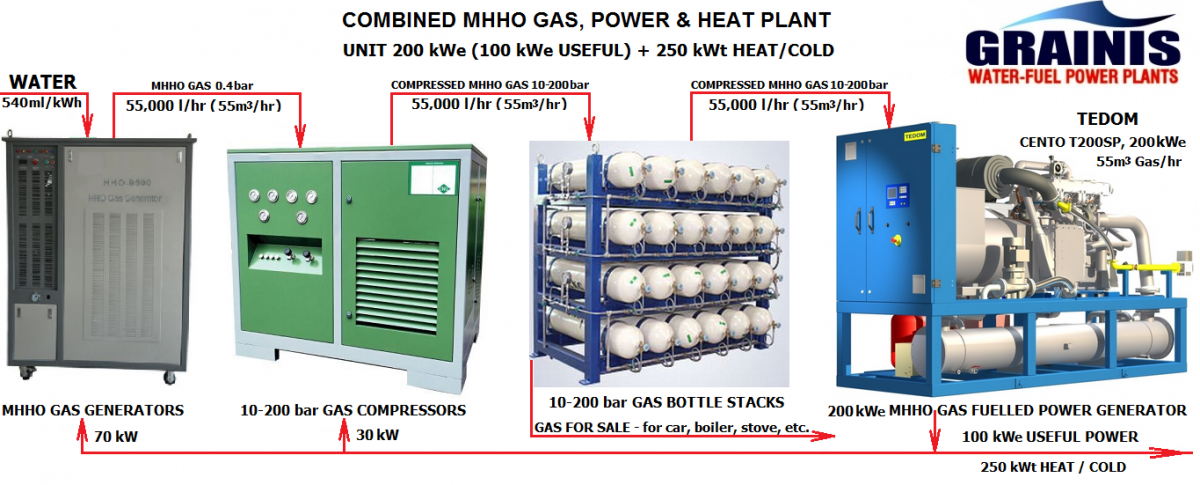

Applying low-frequency Ultrasonic and special nano-bubble re-circulation methods, a new, Modified OH (MOH, MHHO) gas is being produced, which, unlike the regular OH, can be safely compressed over 200 to 1,000 bar, liquefied at 1bar/-178deg.C and combusted as a single fuel in all kinds of gasoline engines, gas turbines, jet/ramjet, impulse-detonation rocket engines and boilers - https://solargas.alle.bg. A similar, but grid-powered Gas was patented in Japan in 2011 by Dr. Ryushin Omasa and called by him Ohmasa Gas.

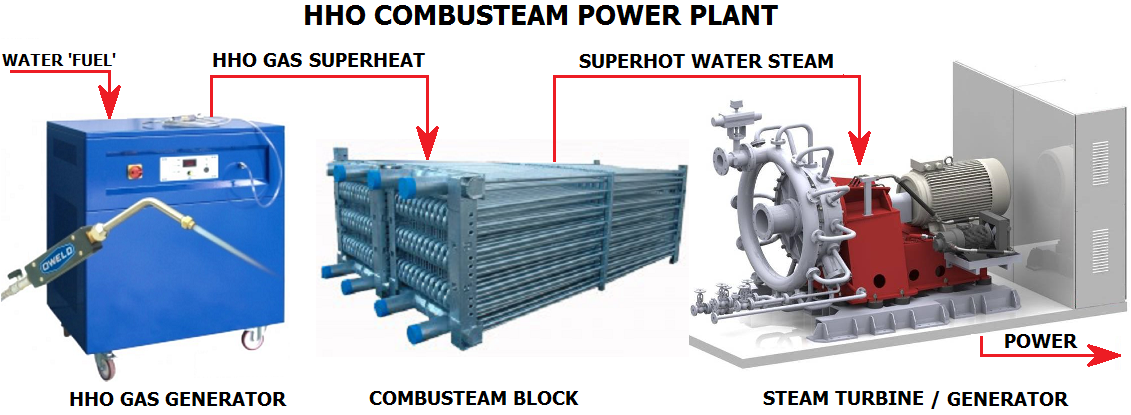

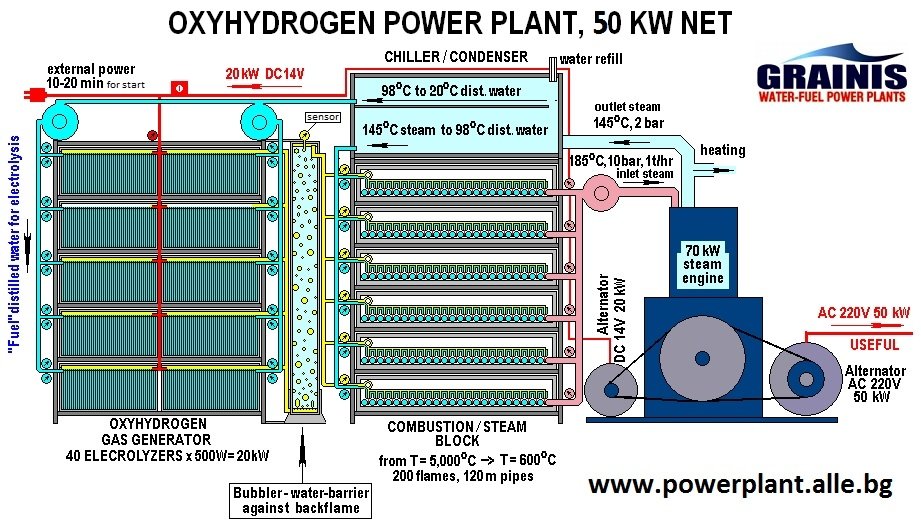

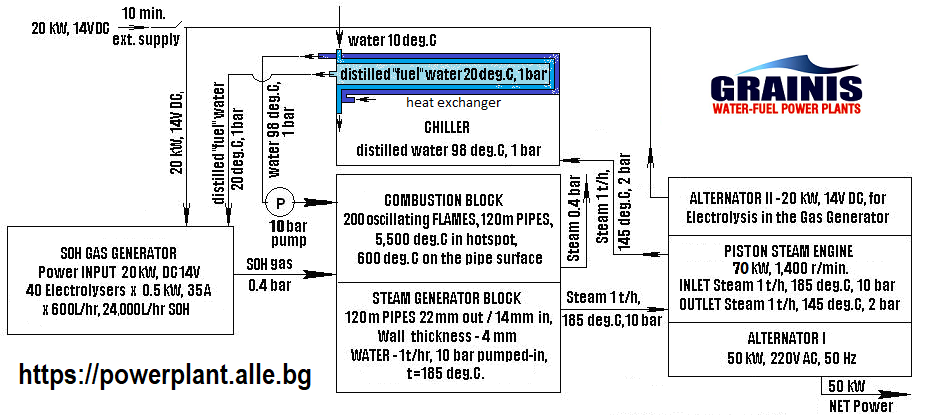

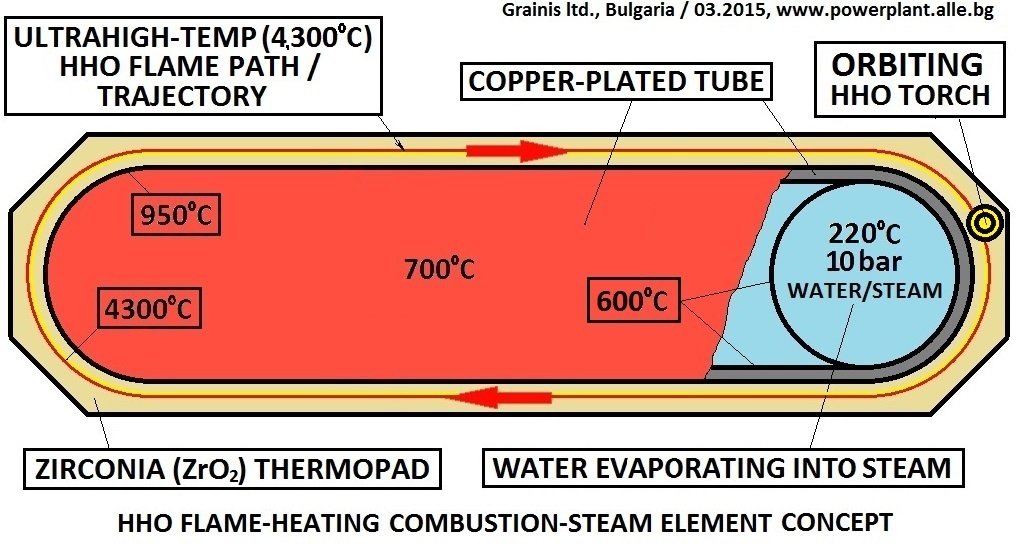

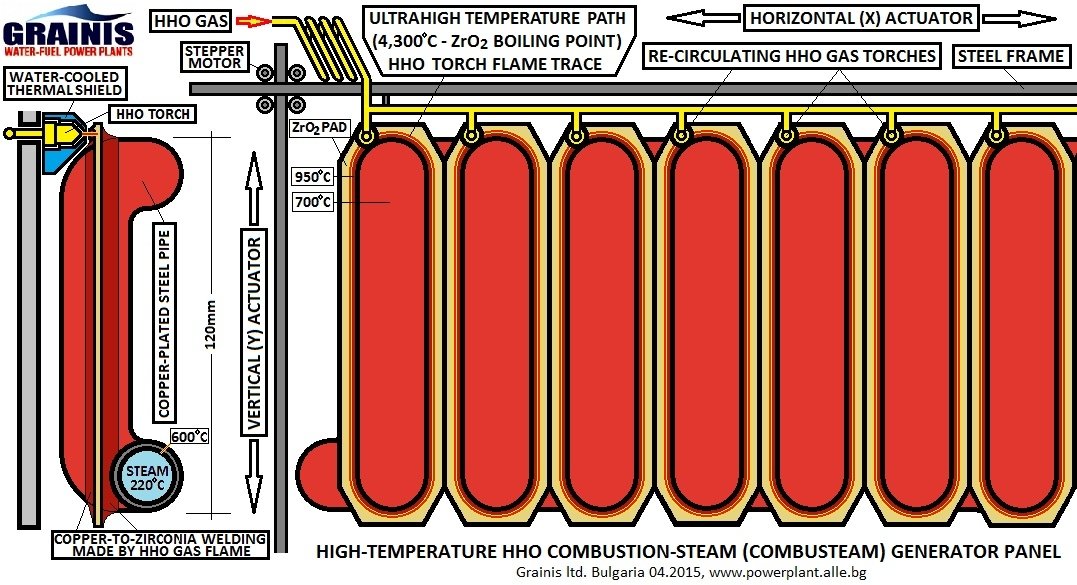

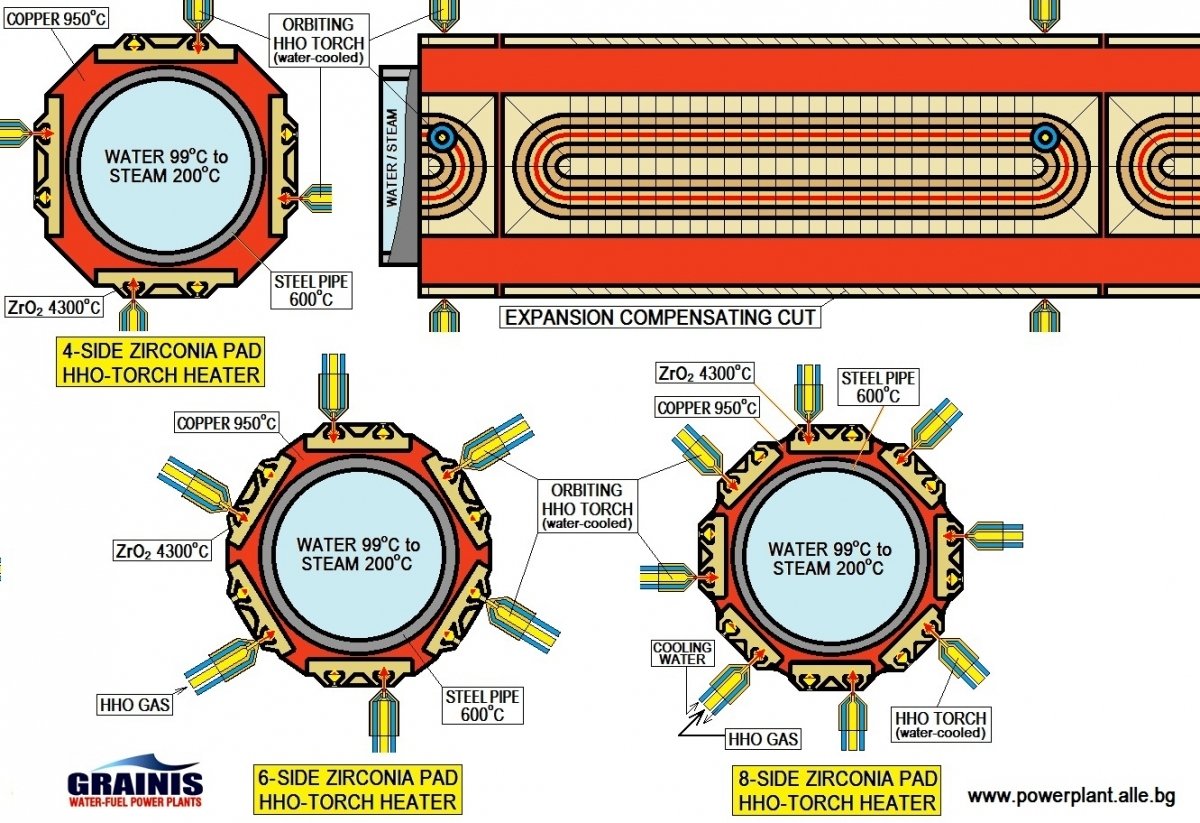

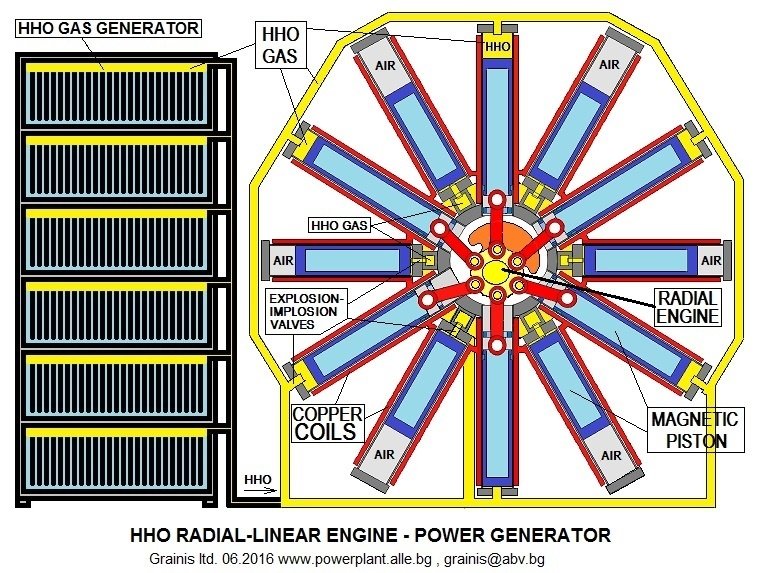

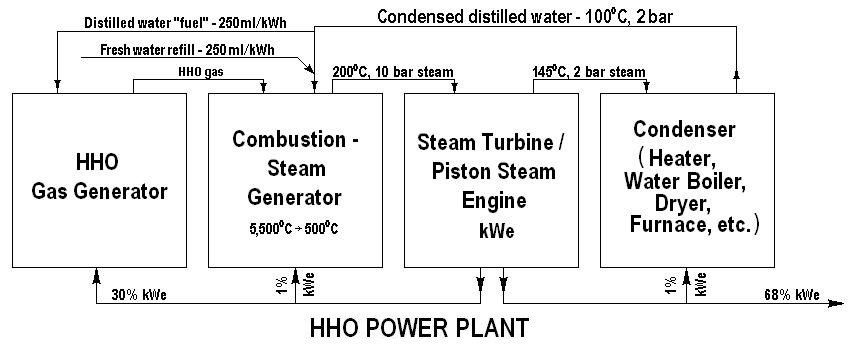

Combining the ultrahigh temperature properties with the ultra-low power consumption for OH production, we elaborated various designs of Power-Autonomous Plants, Generators and Engines, consuming only water (540 ml/kWh), fully recyclable.

We can reach even higher efficiency, applying the Organic Rankine Cycle (ORC) in our Plants.

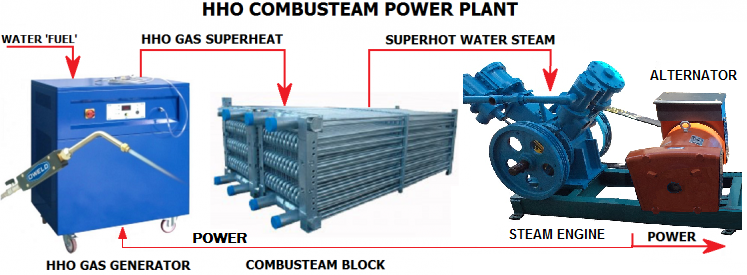

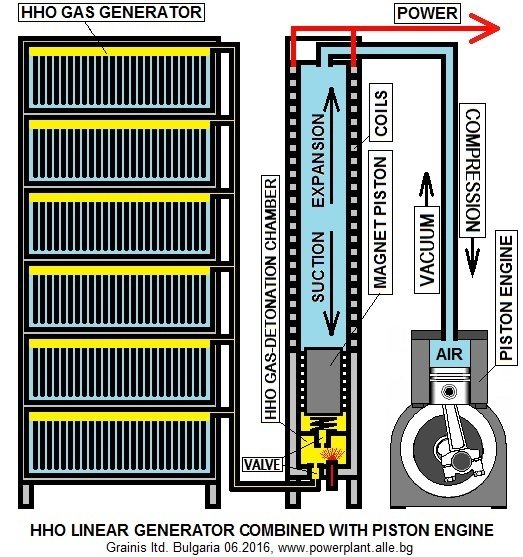

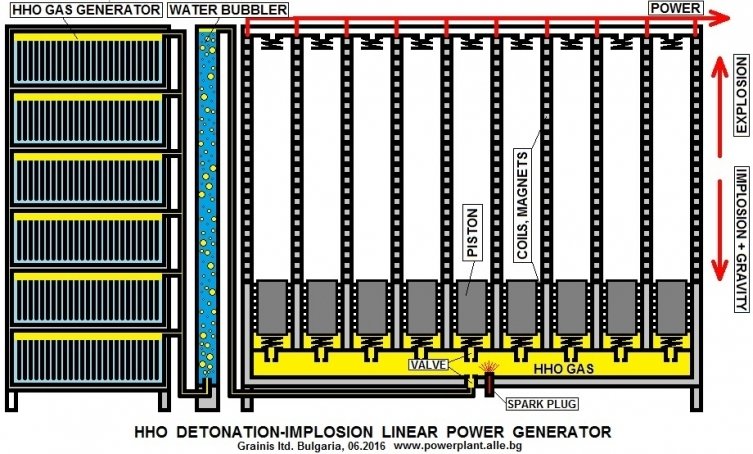

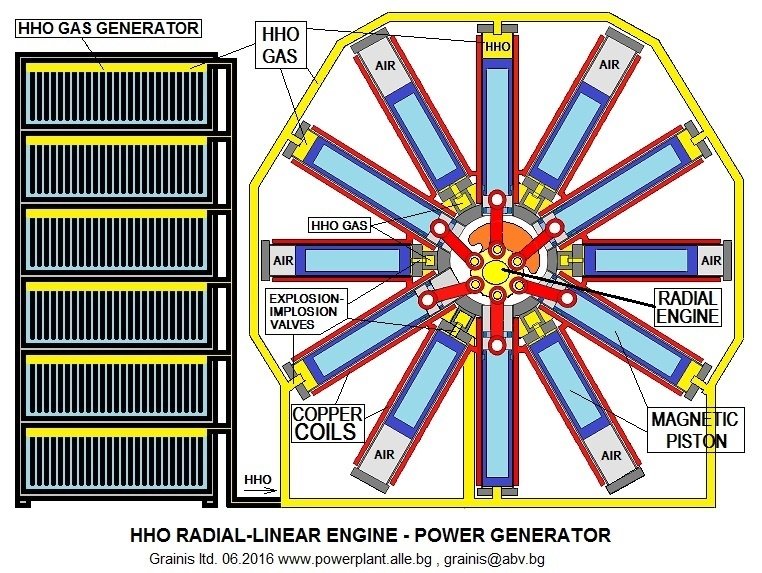

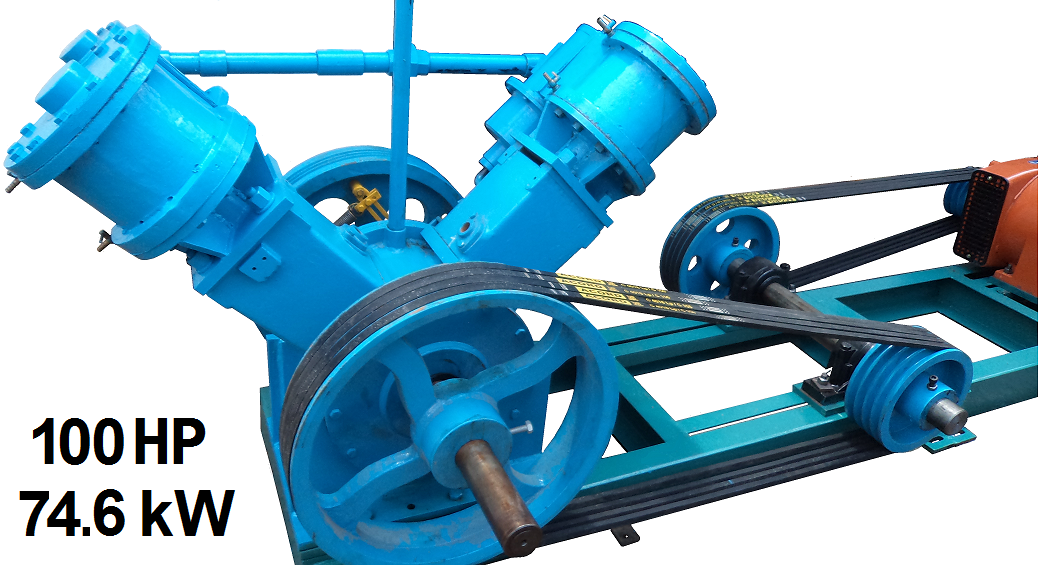

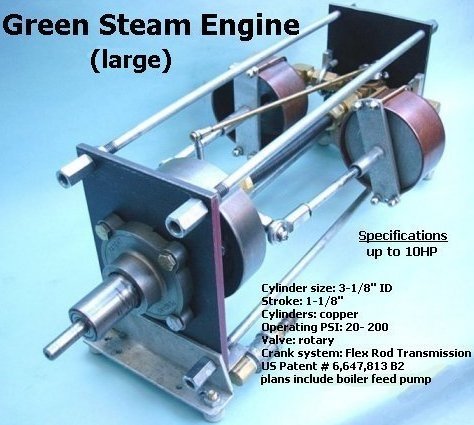

Here are some tentative schemes of our power sets.

We can reach even higher efficiency, applying the Organic Rankine Cycle (ORC) in our Plants.

Here are some tentative schemes of our power sets.

___________________________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________________

__________________________________________________________________________

___________________________________________________________________________________________

___________________________________________________________________________________

_________________________________________________________________________________

NOTE : According to the numerous recent proposals from potential investors, inclusive offers for Bank-Loan, EU-Grant, BG/SBLC instrument or else institutional procedures, please be noted, that we do not need and are NOT interested to join any of such procedures.

_________________________________________________________________________________

NOTE : According to the numerous recent proposals from potential investors, inclusive offers for Bank-Loan, EU-Grant, BG/SBLC instrument or else institutional procedures, please be noted, that we do not need and are NOT interested to join any of such procedures.

_________________________________________________________________________________

Thermal Zones Of The OH's Flame UHTC-Heating

HHO Flame Electro Conductivity - proof it is Ionized Gas (Plasma)

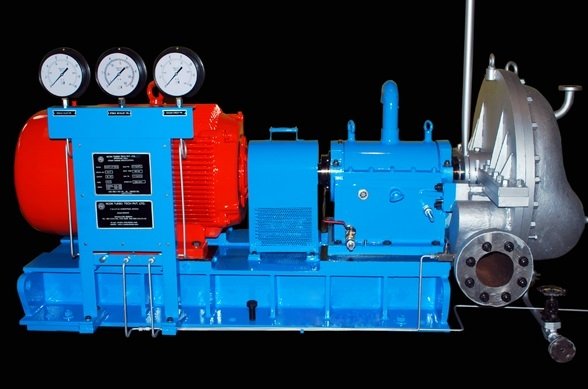

12.5 kW Power Plant Set with FireWood-Fueled Boiler and 20 HP Steam Engine.

Easy OxyHydrogen conversion possible.

Easy OxyHydrogen conversion possible.

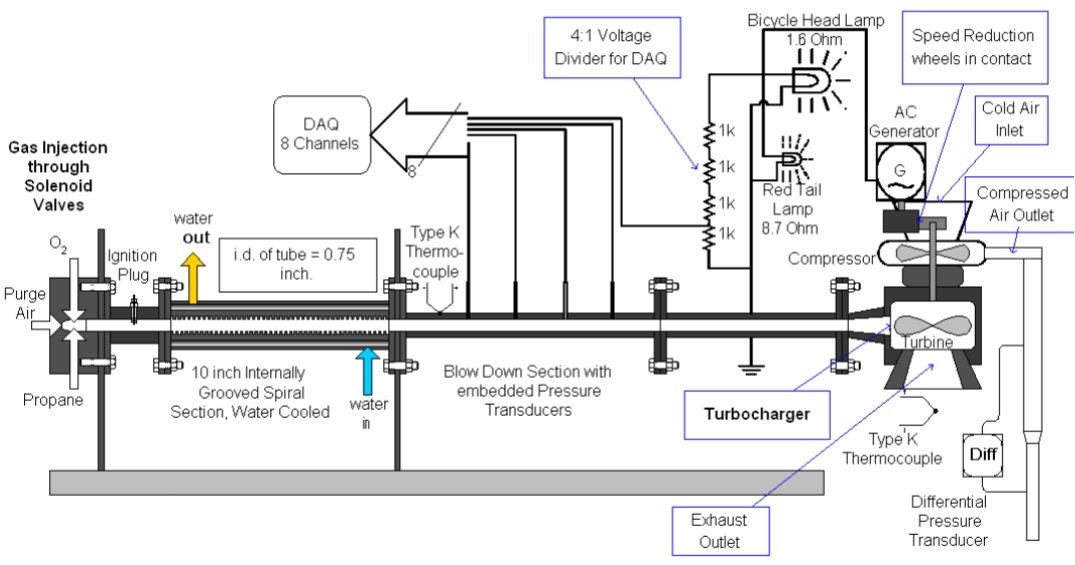

Pulse-Detonation Engine for Power Generation - Texas University, http://arc.uta.edu/publications/pr_files/PDE-TurboGen.pdf

CO2 to Ethanol last discovery

Seebeck's Thermoelectric Generator (TEG) Stack System 3 kW.

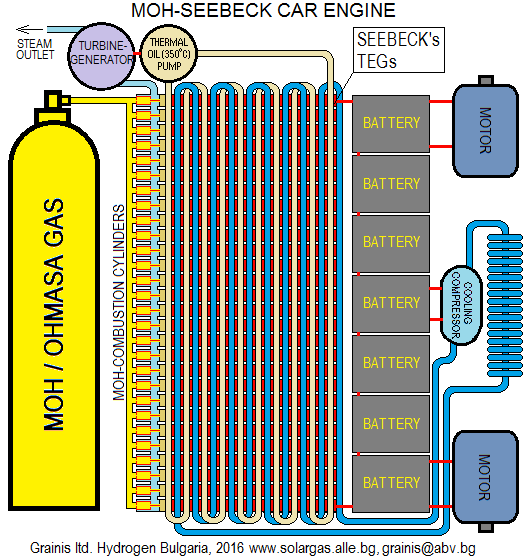

MOH-Seebeck Gas-Electric Car Engine

HHO Torch with capturing and utilizing the reflected flame

Peter Crunk's 36-microflame HHO Burner

HHO's flame is cold - only 137 deg.C |

Welding SS-Ceramic with HHO's Cold-Plasma Flame

TECHNOPA - AUSTRIA, a high-efficient (over 55%COE), innovative "Bristle"- design Impeller Turbine-Generator Set

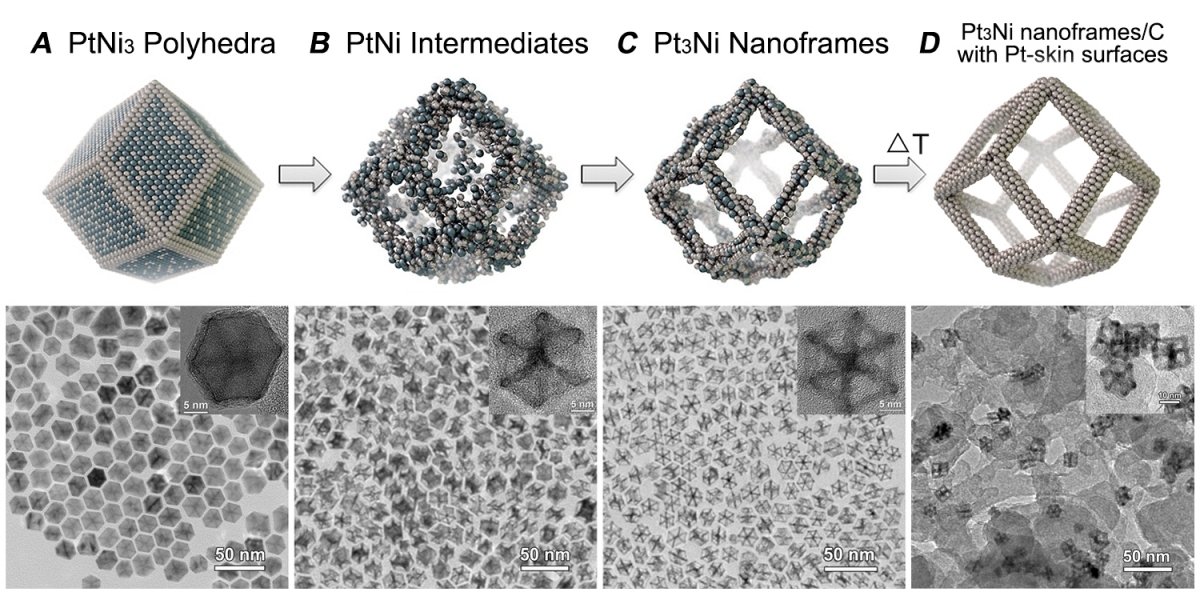

Pt3Ni Polyhedra Catalyst for High-Effective Water Electrolysis.

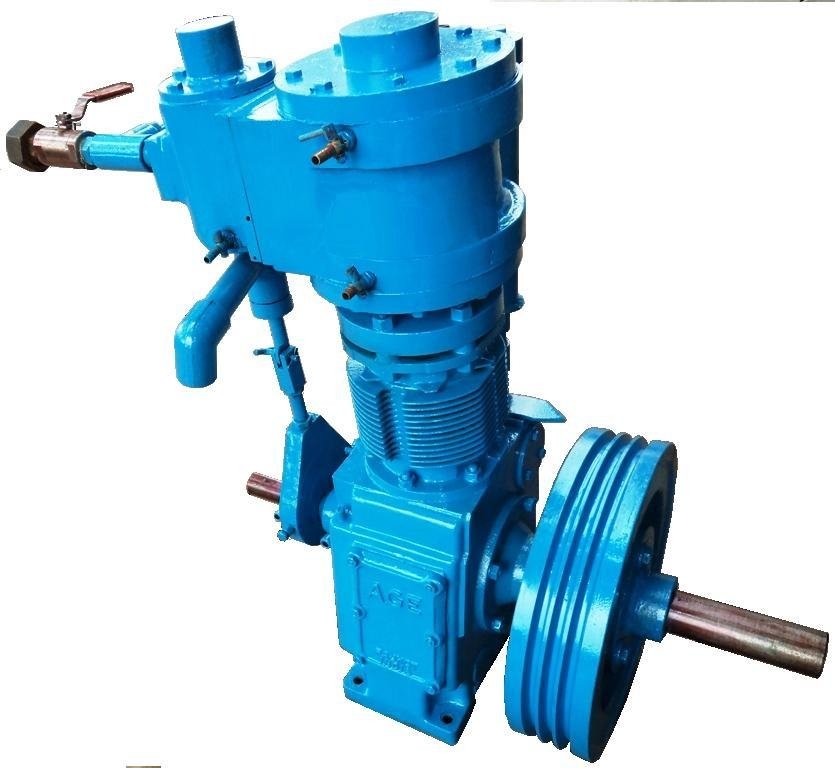

Steam Engine 20 HP, 12.5 kW, Steam : 16 kg/HP/hr, 10 Bar, 185 deg.C

HHO cutting 50 mm steel - VIDEO

Helical tube heaters 5-1000 kW

Seebeck's Thermoelectric Steam Generator

OH (HHO) Power Plant with 0.4Wh/L OH Gas Generator

________________________________________________________________________________________

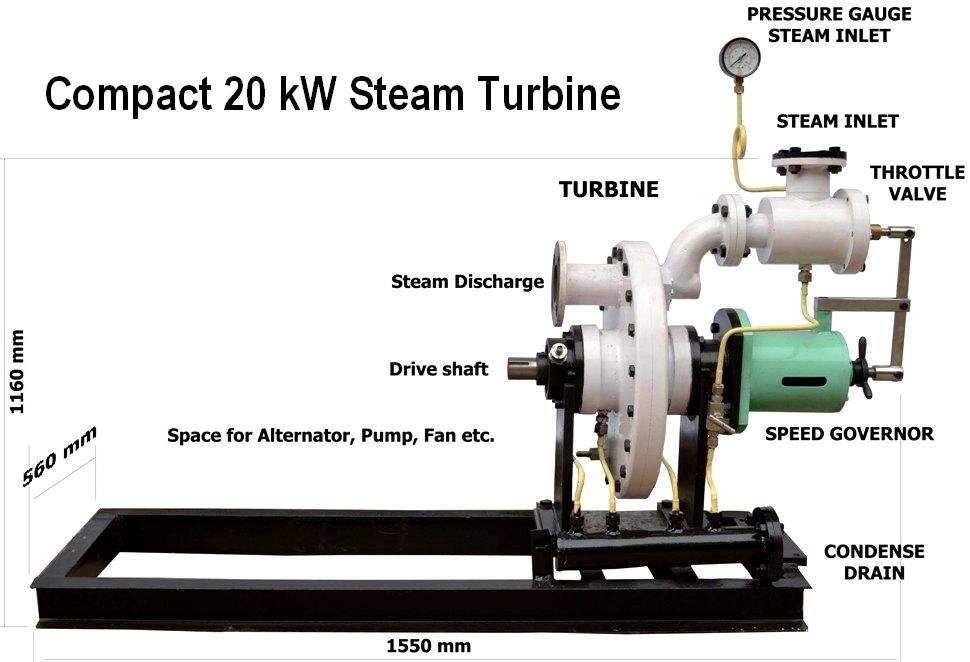

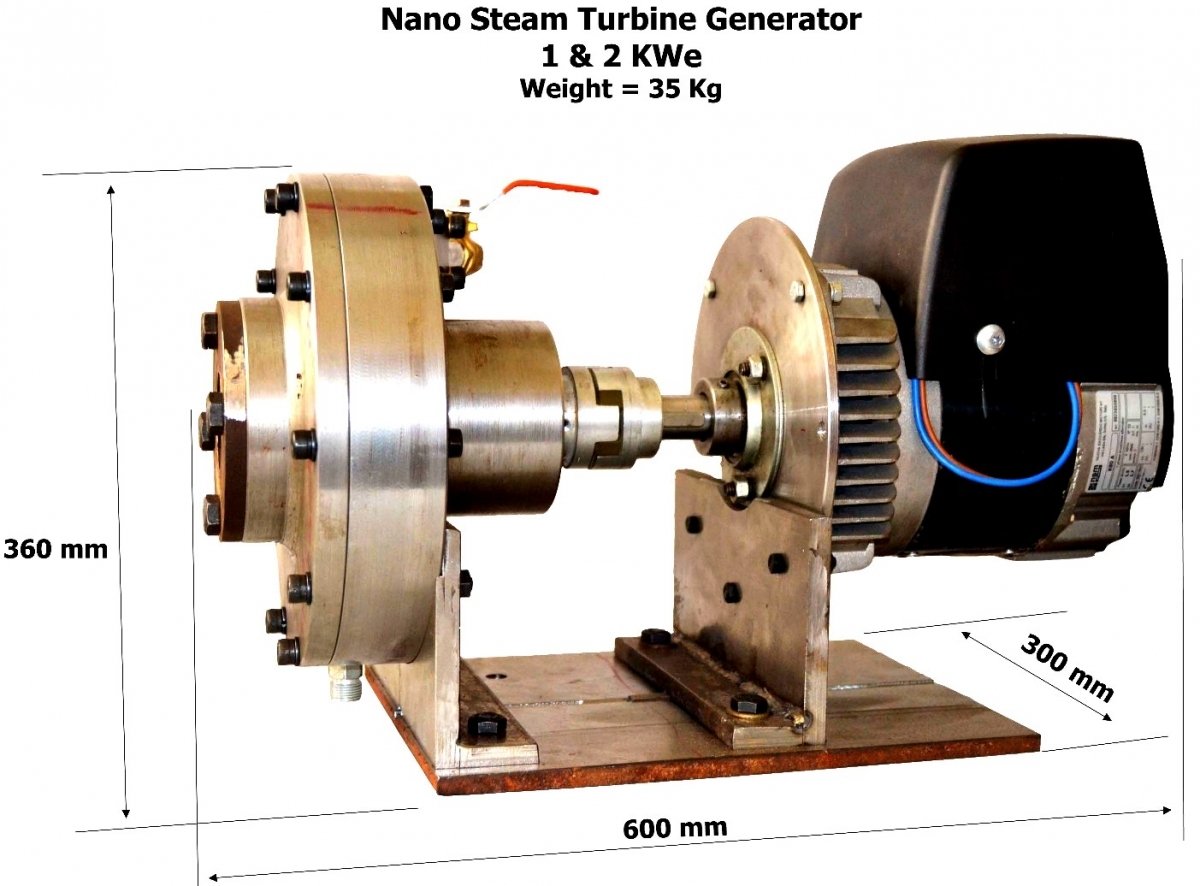

Small, Mini-, Micro- and Nano-Turbines from China and India

___________________________________________________________________________________________

___________________________________________________________________________________________

We offer utilization of various tail gases, produced as a waste out of various manufactures, as hydrogen, nitrogen, oxygen, CO, CO2, SO2, etc., up to final soldable product as clean, or hydrocarbon fuel, fertilizer or energy. We can convert any IC engine-generator to work on hydrogen or MHHO (Ohmasa Gas) and we can offer installations for the hydrogen and MHHO gas fuels production out of water, at a cost, close to zero.

CONTACTS :

GRAINIS LTD

5 Gen. Edward Totleben blvd.

Ruski Pametnik sq.

1606 Sofia, Bulgaria

cell : +359 89 9171570 ( Bg, En, Ru, Mon.-Sat. 9AM-9PM EET )

grainisbg@gmail.com

grainis@abv.bg

grainisbg@gmail.com

grainis@abv.bg

https://hydrogen.alle.bg , https://solargas.alle.bg , https://coal-to-gas.alle.bg , https://basalt.alle.bg , https://passive-house.alle.bg , https://airship.alle.bg , https://flycar.alle.bg , https://flyroad.alle.bg , https://floatland.alle.bg , https://desert.alle.bg , https://basic-income.alle.bg , https://zero-hunger.alle.bg

OUR WORLDWIDE AGENTS / PARTNERS :

НАШИ АГЕНТИ И ПАРТНЬОРИ ПО СВЕТА :

for USA, Central America, Africa

Mr. Phillip Brown

Brown Energy Group Inc.

Mr. Phillip Brown

Brown Energy Group Inc.

3550 NW 112th Street

Miami Florida 33186 USA

PH: 954-800-4289

FX: 954-688-2533

Cell: 305-389-1991

E-mail: Phillip.B@BrownEnergyGroup.com

for South-East Asia :

Mr. Ahmad Fakar, President Director

Mr. Ahmad Fakar, President Director

PT. Nurin Inti Global, Jl. Mertilang IV, no: 3, Bintaro Jaya IX, Tangerang - Banten 15229, Indonesia

Cellphone no: +6281281730794

Email : afakar@gmail.com